ZhuoTe®

Three Ways to Steel Grating Installation & Installation Procedures

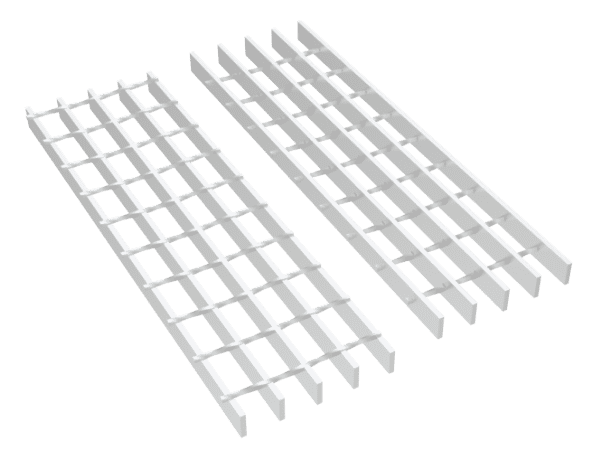

According to its practical application, steel grating can be installed and fixed in many ways. Typically, welding installation, fastener fixing and angle steel fixing are three methods we commonly used for steel grating installation. You can choose a proper installation method suitable for your application.

Preparation before Installation

Before installing the steel gratings, please read the layout drawings and packing list carefully. Unpack the packaging box as required to avoid improper unpacking resulting in a field mess and reducing the work efficiency.

When the unpacking and reading is completed, please place steel gratings in their corresponding locations as required by layout drawings or their code number.

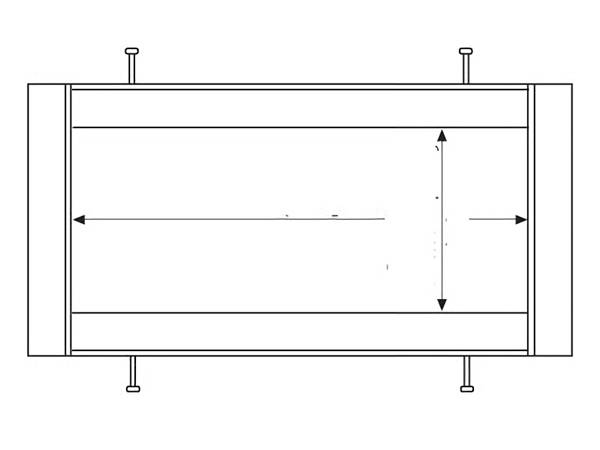

Installation clearance: The installation clearance between steel gratings shall fall within 5–10 mm for facilitating field installation and fine-tuning.

Common Installation Methods

Welding Installation

-

Description

Welding installation refers to the method of fixing steel gratings by welding. It is suitable for steel gratings require a permanent fixing. For the purpose of permanent fixing, steel gratings are welded under the supporting steel bar to form a permanent connection. It is characterized by simple installation, solid structure and reasonable price.

Installation Steps

Paint, rust, oil, water and other dirt must be removed from the surfaces of supporting steels and steel gratings before welding.

Sequence welding is adopted. Welding is generally performed at four corners of the steel grating. If the steel grating is subject to continuous heavy loads, additional welding points shall be added to strengthen its welding firmness.

When the welding is completed, anti-rust paint is manually sprayed on the weld joints to protect the surface of the steel grating from rusting.

Fastener Fixing

-

Description

Fastener fixing refers to the method of fixing steel gratings with fasteners. It is specially designed for steel gratings require frequent removals when the installation is finished. It facilitates the equipment installation, testing and maintenance.

-

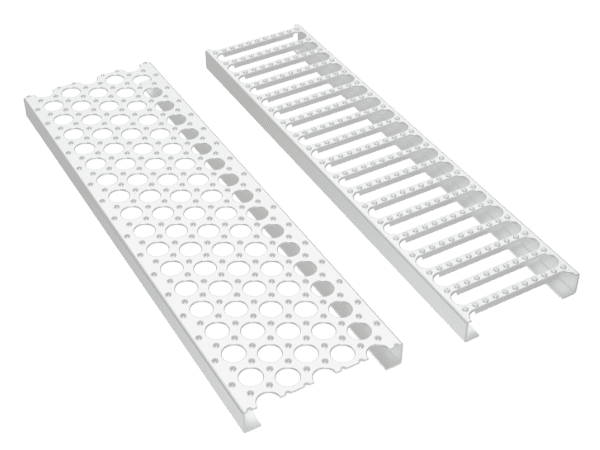

Fasteners

Generally, 4 fasteners per square meter is recommended and installed on the four corners of the steel grating. Additional fasteners are used on steel gratings with a longer unsupported span. Common fasteners include saddle clips, grate quick clips and G-clips as shown below.

-

Installation Steps:

Fastener fixing – saddle clip

Fastener fixing – grate quick clip

Install the upper clip. Put the upper clip on the upper surface of the steel grating. Saddles are aligned to connect two adjacent bearing bars of the steel grating.

Install the lower clip. Put the lower clip on the lower surface of the steel grating and against the steel beam of the steel grating. Saddles are buckled tightly with corresponding bearing bars. It is noted that the lower clip hole and the upper clip holes shall be aligned.

Install bolts and nuts. When the upper and lower clips are correctly installed, insert the bolts to the upper and lower clips through the bolt holes, and tighten the nuts from bottom to top.

Angle Steel Fixing

-

Description

The angle steel fixing method is simple and practical, eliminating the need for welding and steel grating fasteners. The steel grating can be easily removed for equipment maintenance under the steel grating. As it is easy to lose and be stolen, we can provide supporting security locks to secure the safe use of steel gratings with angle steel fixing.

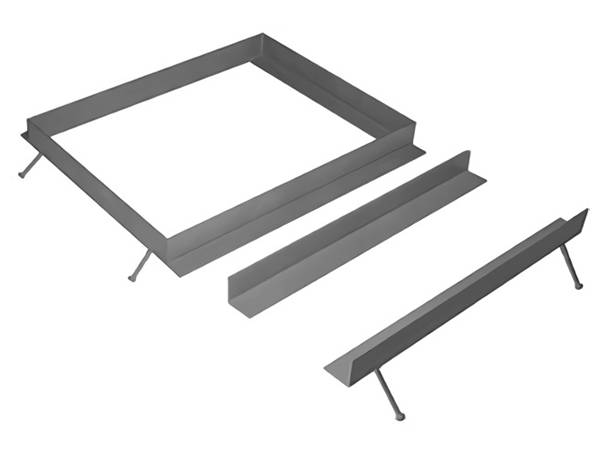

Angle steel installation diagram

-

Installation steps

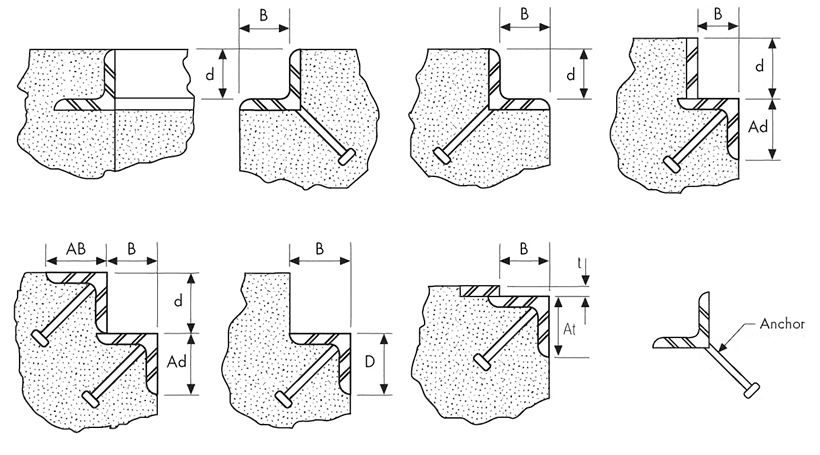

Steel grating foundation concreting

Fix two angle steels on both sides of the groove;

The steel grating is inlaid in the angle steels, and then fill the bottom of the angle steel with cement mortar.

When the steel grating is inlaid into the angle steel, bolts are used to tighten the steel grating to ensure the strength of the foundation.