ZhuoTe®

Stair Tread Steel Grating – High Strength, Safety, Fireproof

Stair tread steel gratings, also called grating steps, are made of low carbon steel or stainless steel. It is one of the most widely used and popular types of steel gratings. With the features of high strength, high bearing capacity, wear resistance, resistance to extreme temperature wind and rain, non-slip, anti-corrosion, beautiful and easy to install and remove extend the lifespan, stair tread steel grating is widely used as different types of steel ladders in the factory, school, park, stadium, civil and commercial buildings.

Different classifications of stair tread steel grating

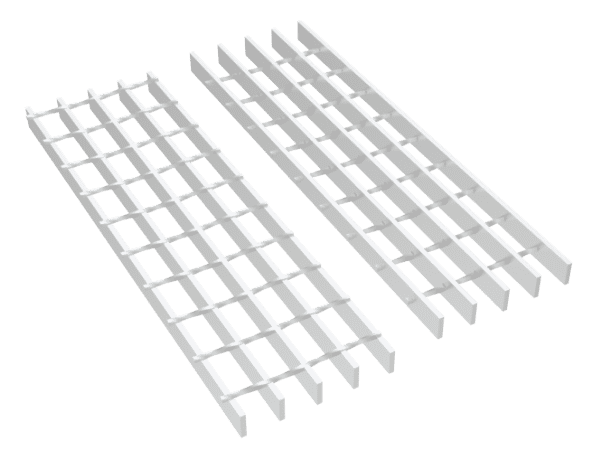

According to the different production methods, straight stair tread steel grating can be divided into welded stair tread, press-locked stair tread, swage-locked stair tread and riveted stair tread.

Welded stair tread is the most widely used type in most industrial and commercial applications, it is easy to install.

Press-locked stair tread and swage-locked stair tread can provide higher strength, and when the surface type is serrated surface, it is more safety.

-

Riveted steel stair tread have a greater load carrying capacity and greater walking comfort.

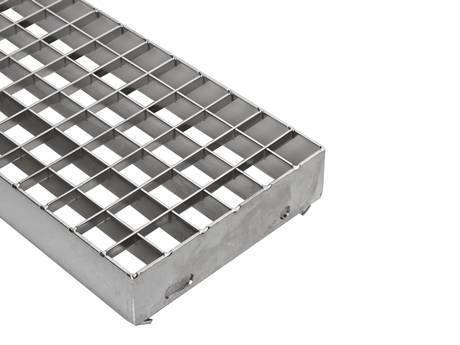

STG-01: Welded stair tread steel grating with checker plate nosing.

STG-02: Press-locked stair tread steel grating without nosing.

STG-03: Swage-locked stair tread steel grating with checker plate nosing.

STG-04: Riveted stair tread steel grating without nosing.

-

According to the different types of surface, straight stair tread steel grating can be divided into smooth stair tread and serrated stair tread.

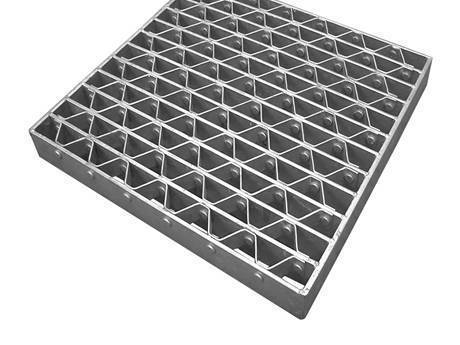

STG-05: Smooth stair tread steel grating.

STG-06: Serrated stair tread steel grating.

According to the different installation method, straight stair tread steel grating can be divided into welding connections stair tread and bolts connections stair tread.

Welding connections stair tread: It is directly welded to the bearing bar, do not need to add end bar, compared with bolts connections stair tread, it is more economical and durable but not easy to dismantle.

Bolts connections stair tread: On both sides of the stair tread need to end bar, poke on the end bar and fix it by bolts, it can be reused.

-

Customers can be customized according to their actual needs, the appropriate type of steel grating made into a variety of sizes.

STG-07: Stair tread steel grating can fixed by welding.

STG-08: Stair tread steel grating can fixed by bolts.

-

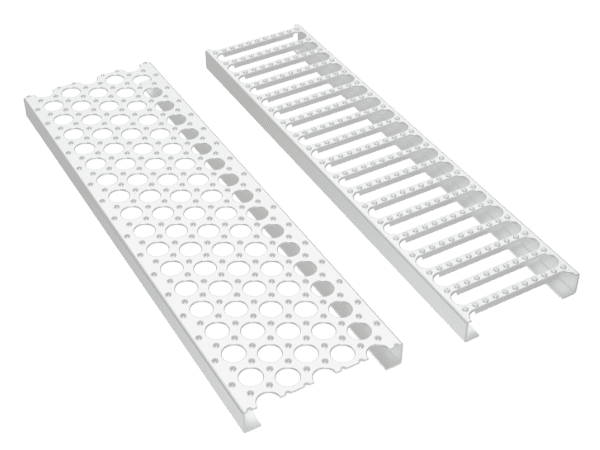

According to the different front nosing, straight stair tread steel grating can be divided into without nosing, checker plate nosing, vertical stripped plate nosing, round hole plate nosing and abrasive nosing.

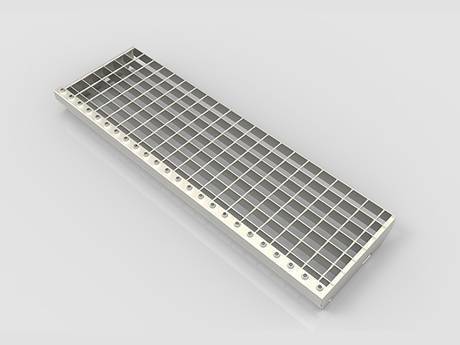

STG-09: Stair tread steel grating without nosing.

STG-10: Stair tread steel grating with checker plate nosing.

STG-11: Stair tread steel grating with vertical stripped plate nosing.

STG-12: Stair tread steel grating with abrasive nosing.

STG-13: Stair tread steel grating with round hole plate nosing.

-

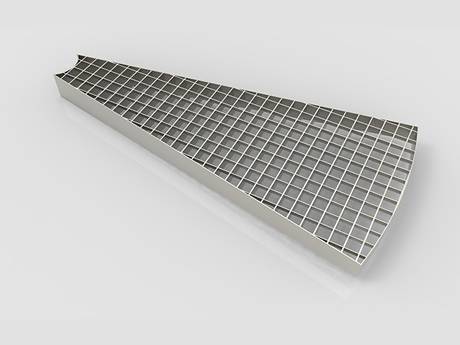

According to the different shapes of stair, stair tread steel grating can be divided into straight stair tread steel grating and spiral stair tread steel grating.

STG-14: Straight stair tread steel grating.

STG-15: Spiral stair tread steel grating.

Specifications of straight stair tread steel grating

Materials: low carbon steel, stainless steel grating.

Surface treatment: hot galvanized, painted, spray coating.

Table 1: Standard sizes of straight stair tread steel grating

| Width (mm) |

600 |

700 |

800 |

900 |

1000 |

1100 |

1200 |

| Depth (mm) |

240 |

270 |

240 |

270 |

240 |

270 |

305 |

240 |

270 |

305 |

240 |

270 |

305 |

270 |

305 |

240 |

270 |

305 |

Packaging:

Strap packing: Generally used for neat press locked steel grating.

Pallet packing: Generally for the press-locked steel grating which need to export and load in container.

Screw rod fixation: Use four screw rods through the mesh and fixed with screws.

STG-16: Stair tread steel grating on pallet.

Standard of stair tread steel grating: BS4592 industrial type flooring and stairs.

Features of stair tread steel grating

Applications of stair tread steel grating

STG-17: Straight stair used in the factories.

STG-18: Spiral stair used in the civil buildings.