MI-1: Steel grating can be widely used in mining industry.

Professional Steel Grating & Safety Grating Manufacturer

- Home

- Steel Grating

ZhuoTe® Steel Grating

- Galvanized Steel Grating

- Stainless Steel Grating

- Aluminum Grating

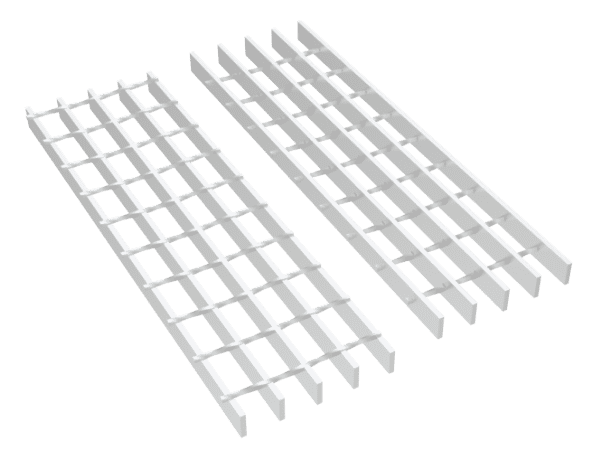

- Welded Steel Grating

- Press-locked Steel Grating

- Swage-Locked Grating

- Riveted Grating

- I Bar Steel Gratings

- Louver Steel Grating

- Standard Steel Grating

- Heavy Duty Steel Grating

- Dense Steel Grating

- Irregular Steel Grating

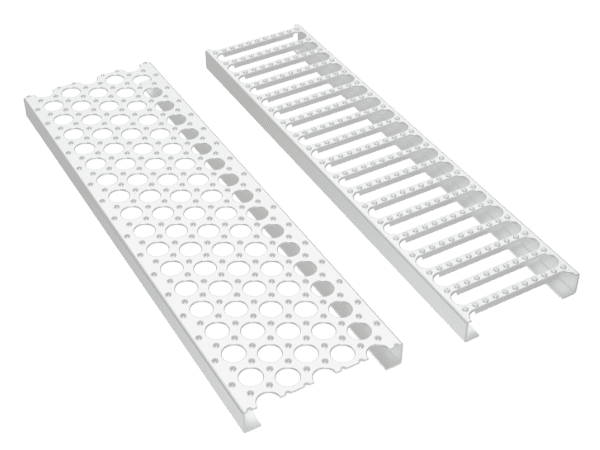

- Compound Steel Grating

- Steel Grating Accessories

- Grating Stanchion Railing Ball Joint Handrail

- Serrated Welded Steel Grating

- Serrated Press-Locked Steel Grating

- Plug Grating

- Safety Grating

- Application

ZhuoTe® Application

- Stainless Steel Wedge Wire Floor Grate

- Aluminum Gutter Guard

- Swaged Louvers

- Platform Grating

- Walkway Grating

- Stair Tread Steel Grating

- Trench Cover Grating

- Grating Fence

- Handrail Infill Grating

- Bridge Decking Grating

- Transformer Gratings

- Steel Grating Ceiling

- Steel grating Sun Shade Panels

- Steel Grating Floor

- Steel Grating Operating Platform

- Steel Grating Drilling Platform

- Steel Grating Tree Cover

- Steel Grating Balcony Fence

- Pipeline Floor Grating

- Steel Grating Partition Panels

- More Application +

- Projects

ZhuoTe® Projects

- Service

ZhuoTe® Service

- About Us

- Contact Us